From Industrial Applications to Cutting-Edge Tech: Superhard Materials Market Analysis

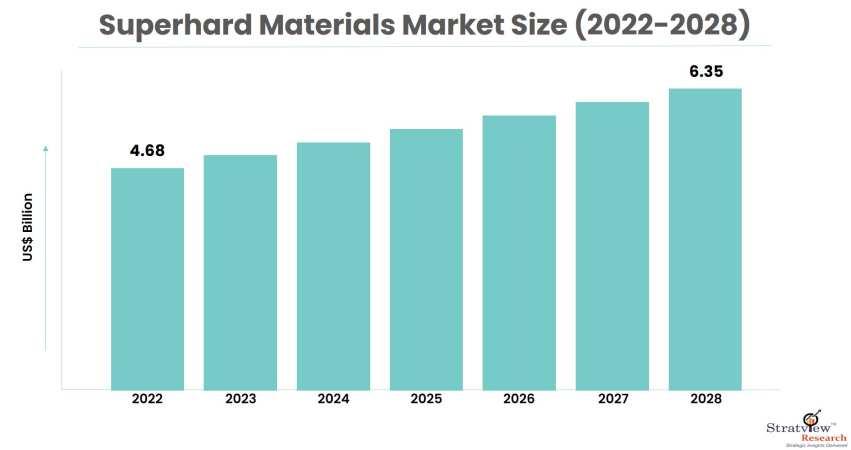

Superhard materials have revolutionized various industries, from manufacturing to electronics, with their exceptional properties. These materials possess extraordinary hardness, wear resistance, and thermal conductivity, making them invaluable for a multitude of applications. As technology advances, the demand for superhard materials continues to soar, fueled by innovations in industrial processes and emerging technologies. According to Stratview Research, the global superhard materials market size was valued at USD 4.68 billion in 2022 and it is projected to reach USD 6.35 billion by 2028, growing at a CAGR of 5.10% during forecast period of 2023-2028. In this article, we delve into the dynamics of the superhard materials market, exploring its growth drivers, key players, and future prospects.

The Evolution of Superhard Materials:

The journey of superhard materials began with the discovery of diamond and cubic boron nitride (CBN) in the mid-20th century. These materials, with their unmatched hardness, quickly found applications in cutting, grinding, and drilling operations across various industries. However, their high cost and limitations in certain applications spurred the quest for alternative superhard materials.

Over the decades, significant advancements have been made in the synthesis and application of superhard materials. Innovations such as polycrystalline diamond (PCD), polycrystalline cubic boron nitride (PCBN), and nanostructured superhard materials have expanded the scope of superhard materials beyond traditional uses. These advancements have not only improved the performance of cutting tools and abrasives but have also enabled the development of new technologies in areas such as electronics, optics, and aerospace.

Market Analysis:

The superhard materials market is witnessing robust growth, driven by several factors:

- Industrial Applications: Superhard materials are extensively used in manufacturing processes such as machining, grinding, and cutting of hard and abrasive materials like metals, ceramics, and composites. The automotive, aerospace, and construction industries are major consumers of superhard materials for tooling and machining applications.

- Electronics and Semiconductor Industry: With the miniaturization of electronic devices and the demand for higher processing speeds, superhard materials play a crucial role in the production of semiconductor components. Diamond-based materials are utilized for precision cutting, grinding, and polishing of silicon wafers and other electronic substrates.

- Research and Development: Ongoing research in materials science and engineering is driving the development of new superhard materials with enhanced properties and novel applications. The exploration of nanomaterials, thin films, and composite structures is expanding the frontier of superhard materials, opening up opportunities in areas such as quantum computing, sensors, and biomedical devices.

Key Players:

Several companies dominate the global superhard materials market, including:

- Element Six

- Sandvik AB

- ILJIN Diamond Co., Ltd.

- Sumitomo Electric Industries, Ltd.

- Saint-Gobain Abrasives

These companies are engaged in continuous R&D efforts to improve the performance and cost-effectiveness of superhard materials, thereby maintaining their competitive edge in the market.

Future Prospects:

The future of the superhard materials market looks promising, driven by technological advancements and expanding application areas. Key trends shaping the market include:

- Nanotechnology: The integration of nanomaterials and nanotechnology techniques is expected to lead to the development of superhard materials with superior properties and multifunctionality. Nanodiamonds, graphene, and carbon nanotubes hold immense potential for revolutionizing various industries.

- Additive Manufacturing: The emergence of additive manufacturing, or 3D printing, is opening up new avenues for the production of complex geometries and customized components using superhard materials. Additive manufacturing techniques enable precise control over material properties and offer cost-effective solutions for prototyping and small-batch production.

- Sustainable Solutions: As environmental concerns grow, there is a growing emphasis on sustainable manufacturing practices and eco-friendly materials. Companies are exploring renewable sources of superhard materials and adopting recycling and waste reduction measures to minimize environmental impact.

Conclusion:

The superhard materials market continues to evolve, driven by technological innovations, industrial demand, and market dynamics. With their exceptional properties and versatile applications, superhard materials are poised to play a vital role in shaping the future of manufacturing, electronics, and emerging technologies. As research and development efforts accelerate and new application areas emerge, the market for superhard materials is expected to witness sustained growth and innovation in the years to come.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness