Market Dynamics: Key Drivers Shaping the Automotive Ceramics Industry

The automotive ceramics industry is witnessing significant growth and transformation, driven by various key factors that enhance the performance, efficiency, and sustainability of vehicles. Automotive ceramics are valued for their exceptional properties, such as high strength, durability, resistance to extreme temperatures, and wear resistance. These attributes make them indispensable in modern automotive engineering. This article delves into the key drivers shaping the automotive ceramics industry.

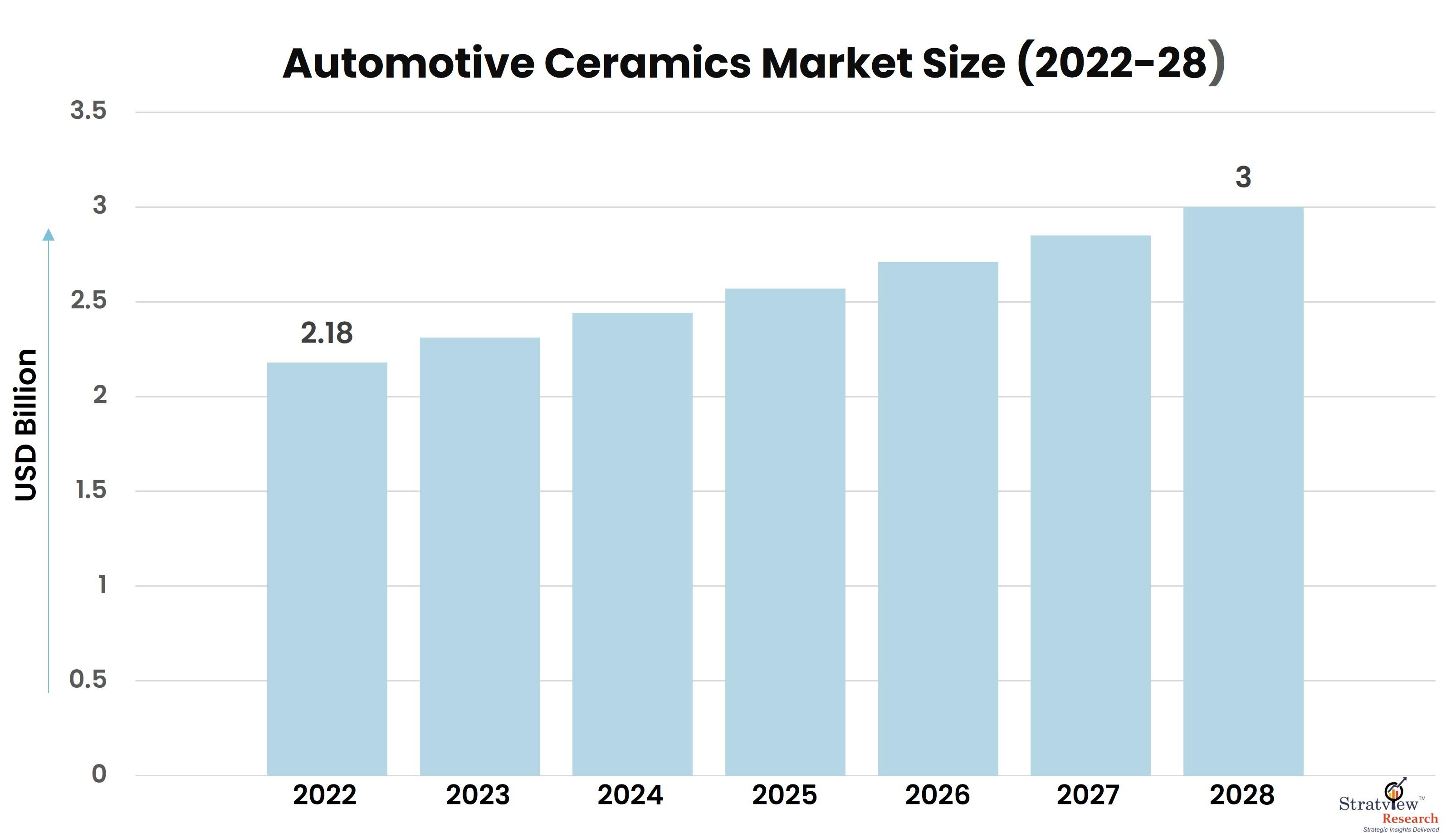

According to Stratview Research, the automotive ceramics market was estimated at USD 2.18 billion in 2022 and is likely to grow at a CAGR of 5.36% during 2023-2028 to reach USD 3 billion in 2028.

Growing Demand for Electric Vehicles (EVs)

One of the primary drivers of the automotive ceramics industry is the rising demand for electric vehicles (EVs). As the world moves towards greener transportation solutions, the adoption of EVs is accelerating. These vehicles require advanced materials that can withstand high temperatures and provide efficient thermal management, especially in battery systems and electric motors. Ceramics are increasingly used in EV components due to their ability to enhance performance and safety. This shift towards electrification is significantly boosting the demand for automotive ceramics.

Technological Advancements

Technological advancements in ceramic materials and manufacturing processes are propelling the automotive ceramics industry forward. Innovations such as additive manufacturing (3D printing) and advanced coating techniques are enabling the production of complex ceramic components with higher precision and reliability. These advancements are expanding the applications of ceramics in the automotive sector, allowing for the development of more efficient and durable parts. Continuous research and development efforts are leading to the creation of new ceramic materials with enhanced properties, further driving industry growth.

Focus on Fuel Efficiency and Emissions Reduction

Automotive manufacturers are under increasing pressure to improve fuel efficiency and reduce emissions. Ceramics play a crucial role in achieving these objectives by providing lightweight and durable solutions that enhance engine efficiency and reduce friction. Ceramic components, such as catalytic converters and particulate filters, are essential for meeting stringent emission standards. The use of ceramics in these applications helps to lower emissions and improve overall vehicle performance, making them integral to the automotive industry's sustainability goals.

Increasing Use of Sensors and Electronics

The integration of advanced sensors and electronic systems in modern vehicles is another key driver of the automotive ceramics industry. Ceramic substrates and components are used in various electronic applications due to their excellent electrical insulation, thermal conductivity, and stability. The rise of autonomous and connected vehicles is further accelerating this trend. As vehicles become more technologically advanced, the demand for high-performance ceramic components in electronic systems is expected to grow.

Conclusion

The automotive ceramics industry is shaped by several dynamic factors, including the growing demand for electric vehicles, technological advancements, the focus on fuel efficiency and emissions reduction, and the increasing use of sensors and electronics. These drivers are not only enhancing the performance and sustainability of vehicles but are also creating significant growth opportunities for the industry. As the automotive sector continues to evolve, the role of ceramics will become increasingly important, driving further innovation and development in the field.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness