The Evolution of Aerial Work Platforms: Past, Present, and Future

Aerial work platforms (AWPs) have transformed how construction, maintenance, and various other industries perform tasks at height. These versatile machines have evolved significantly over the years, enhancing safety, efficiency, and functionality. This article delves into the past, present, and future of aerial work platforms, highlighting key developments and trends that have shaped and continue to shape this vital industry.

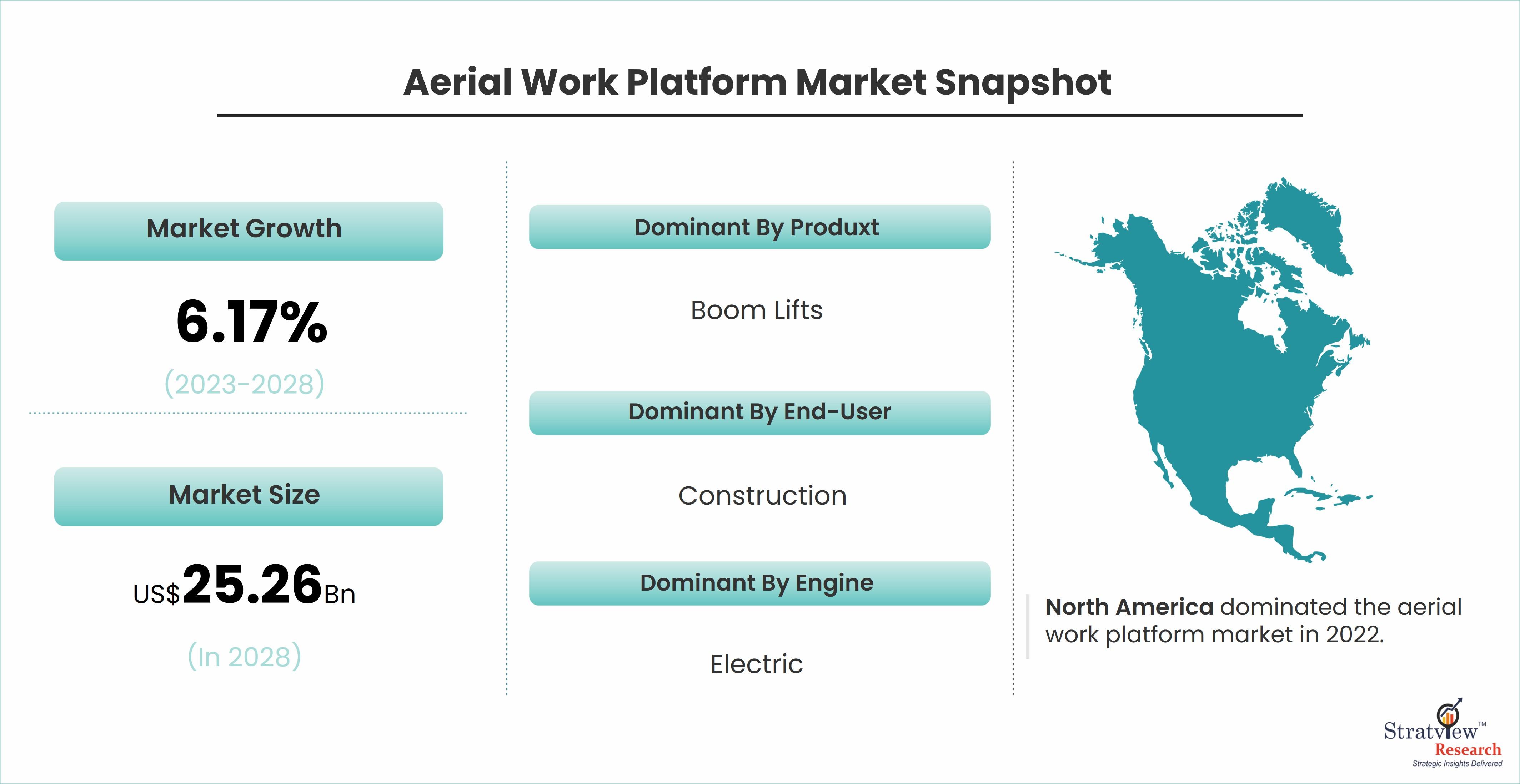

According to Stratview Research, the aerial work platform market was estimated at USD 17.59 billion in 2022 and is likely to grow at a CAGR of 6.17% during 2023-2028 to reach USD 25.26 billion in 2028.

The Past: Origins and Early Developments

The history of aerial work platforms dates back to the mid-20th century when the need for safer and more efficient ways to work at height became apparent. Early versions of AWPs were rudimentary and primarily consisted of manually operated scaffolds and ladders. These methods were not only labor-intensive but also posed significant safety risks.

The first significant leap in AWP technology came in the 1970s with the introduction of hydraulic systems. This innovation led to the development of the first scissor lifts and boom lifts, which offered enhanced stability and reach. Hydraulic-powered lifts allowed workers to raise and lower platforms with greater precision and ease, significantly improving productivity and safety on job sites.

The Present: Advanced Technologies and Applications

Today, aerial work platforms have become indispensable tools across various industries, including construction, maintenance, telecommunications, and warehousing. Modern AWPs are equipped with state-of-the-art technologies that enhance performance, safety, and user experience. Key advancements include:

Hydraulic and Electric Systems: Modern AWPs use advanced hydraulic and electric systems that offer smooth and precise control. Electric-powered AWPs, in particular, have gained popularity due to their eco-friendly nature and reduced noise levels, making them ideal for indoor use.

Enhanced Safety Features: Safety remains a top priority in the design of AWPs. Features such as automatic leveling systems, overload sensors, and emergency descent mechanisms have become standard. Additionally, modern AWPs are equipped with guardrails, harness attachment points, and anti-slip platforms to ensure worker safety.

Versatility and Accessibility: AWPs now come in various forms, including scissor lifts, boom lifts, cherry pickers, and vertical mast lifts, catering to different applications and environments. They offer varying reach heights and platform sizes, providing flexibility and accessibility for a wide range of tasks.

Telematics and Connectivity: The integration of telematics and connectivity solutions has revolutionized AWP operations. These systems allow for real-time monitoring of machine performance, maintenance schedules, and location tracking. Telematics enhance fleet management, reduce downtime, and improve overall efficiency.

The Future: Innovations and Emerging Trends

The future of aerial work platforms looks promising, with several exciting trends and innovations on the horizon. These advancements are expected to further enhance the capabilities, safety, and sustainability of AWPs.

Autonomous and Remote-Controlled AWPs: The development of autonomous and remotely controlled AWPs is set to revolutionize the industry. These machines will be able to navigate and operate in challenging environments without direct human intervention, reducing the risk of accidents and increasing efficiency.

Sustainable Materials and Energy Sources: The push for sustainability is driving the adoption of eco-friendly materials and energy sources in AWP manufacturing. Future AWPs are likely to incorporate lightweight, durable materials and be powered by renewable energy sources, such as solar or hydrogen fuel cells.

Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies have the potential to enhance training and operational efficiency. AR can provide operators with real-time information and guidance, while VR can simulate realistic training scenarios, improving skill development and safety awareness.

IoT Integration and Predictive Maintenance: The Internet of Things (IoT) will play a crucial role in the future of AWPs. IoT-enabled sensors and devices will provide continuous data on machine health, enabling predictive maintenance and reducing downtime. This proactive approach will lead to longer machine lifespans and lower operating costs.

Conclusion

The evolution of aerial work platforms from simple manual devices to sophisticated machines has significantly impacted various industries by improving safety, efficiency, and productivity. As technology continues to advance, the future of AWPs holds even greater promise with the potential for autonomous operation, sustainable materials, and enhanced connectivity. These innovations will not only transform how work is performed at height but also contribute to safer and more sustainable practices across the board.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness