Diamond Substrate: The Future of Advanced Materials

In the realm of advanced materials, few substances hold as much promise as diamond substrates. Known for their unparalleled hardness and exceptional thermal conductivity, diamond substrates are revolutionizing industries ranging from electronics to quantum computing. As researchers and engineers continue to unlock their potential, it is becoming increasingly clear that diamond substrates are not just a scientific curiosity but a cornerstone of next-generation technologies. In this article, we will explore what makes diamond substrates unique, their applications, and the transformative role they play in modern science and industry.

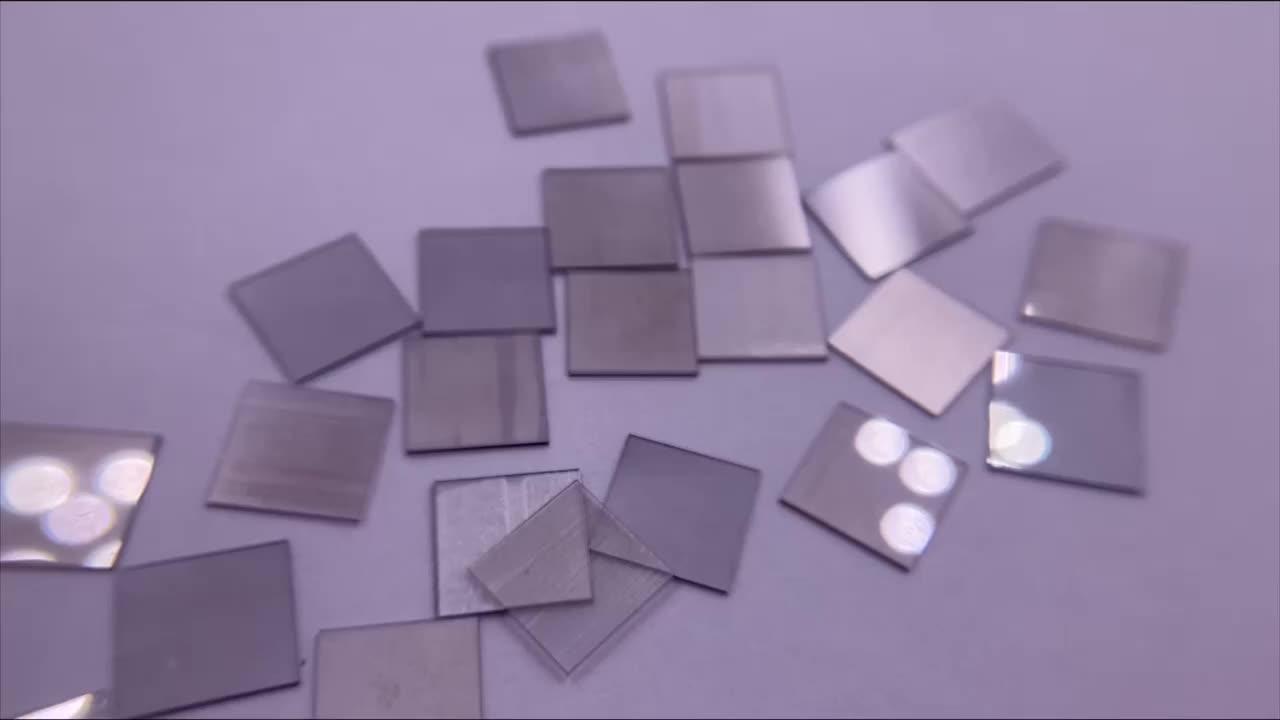

A diamond substrate is a thin layer of diamond material, often synthetic, that serves as a foundational layer for various technological applications. Unlike natural diamonds, which are typically used in jewelry, synthetic diamond substrates are engineered for specific industrial purposes. They are created through processes such as chemical vapor deposition (CVD), which allows for precise control over the diamond’s properties, including its purity, thickness, and crystal structure.

The exceptional properties of diamond substrates stem from the inherent characteristics of diamond itself. Diamond is the hardest known natural material, making it highly resistant to wear and tear. It also has the highest thermal conductivity of any material, allowing it to efficiently dissipate heat. These qualities, combined with its electrical insulating properties and optical transparency, make diamond an ideal material for a wide range of advanced applications.

The Diamond Substrate Market is experiencing robust growth, expanding at a notable CAGR of 12.9% between 2021 and 2031. This rapid growth is fueled by the increasing demand for diamonds in advanced applications, particularly in medical devices and equipment, where diamond substrates are valued for their exceptional thermal conductivity, biocompatibility, and durability.

The market is projected to reach a valuation of US$ 282.38 million by 2031, driven by advancements in technology and the growing adoption of synthetic diamonds in industrial and electronic applications. Diamond substrates are increasingly utilized in high-power electronics, optoelectronics, and semiconductor devices, where their superior properties improve performance and efficiency. Additionally, their use in cutting-edge medical tools and diagnostics has further elevated their demand.

With expanding applications across diverse industries and ongoing innovation in synthetic diamond production, the diamond substrate market is set to play a pivotal role in shaping the future of high-performance materials.

Key Properties of Diamond Substrates

Diamond substrates stand out due to their unique combination of physical, thermal, and optical properties. Some of the key characteristics that make them valuable include:

-

Extreme Hardness: Diamond is renowned for its unparalleled hardness, making it resistant to scratches and deformation. This property is particularly beneficial in applications where durability is critical.

-

High Thermal Conductivity: Diamond substrates can conduct heat more efficiently than any other material, including metals like copper and silver. This makes them ideal for use in high-power electronics and thermal management systems.

-

Electrical Insulation: Despite their excellent thermal conductivity, diamond substrates are electrical insulators. This unique combination is valuable for electronic devices that require thermal dissipation without electrical interference.

-

Optical Transparency: Diamond is transparent to a wide range of wavelengths, from ultraviolet to infrared. This property makes it useful in optical applications, including high-performance lenses and windows.

-

Chemical Stability: Diamond is chemically inert and can withstand harsh environments, including exposure to acids and high temperatures. This durability extends its usability in challenging industrial conditions.

Applications of Diamond Substrates

The unique properties of diamond substrates have opened up a myriad of applications across various industries. Some of the most notable uses include:

-

Electronics and Semiconductors: Diamond substrates are increasingly being used in the electronics industry to improve the performance and reliability of semiconductor devices. Their ability to dissipate heat efficiently makes them ideal for high-power transistors, diodes, and other components that generate significant heat.

-

Quantum Computing: Diamond substrates play a crucial role in the development of quantum computers. Their exceptional optical and thermal properties make them suitable for hosting nitrogen-vacancy (NV) centers, which are used as quantum bits (qubits) in quantum computing systems.

-

Thermal Management: The high thermal conductivity of diamond substrates makes them indispensable in thermal management applications. They are used as heat spreaders and thermal interfaces in devices ranging from lasers to LED lighting systems.

-

Optical Devices: Diamond’s optical transparency and durability make it an excellent material for optical components such as lenses, windows, and beam splitters. These components are used in high-performance optical systems, including those in aerospace and defense industries.

-

Medical Applications: Diamond substrates are finding applications in the medical field, particularly in advanced imaging and diagnostic equipment. Their biocompatibility also opens the door for use in medical implants and biosensors.

-

Cutting Tools and Coatings: Beyond high-tech applications, diamond substrates are used in more traditional industries for cutting tools and protective coatings. Their hardness and wear resistance make them ideal for machining and drilling applications.

The Role of Diamond Substrates in Sustainability

In addition to their technological benefits, diamond substrates contribute to sustainability efforts in several ways. For example, their high thermal conductivity can improve the energy efficiency of electronic devices, reducing overall power consumption. In the lighting industry, diamond-based thermal management systems can extend the lifespan of LED lights, lowering the environmental impact associated with frequent replacements.

Furthermore, synthetic diamond substrates are produced in controlled environments, which reduces the environmental and ethical concerns associated with mining natural diamonds. Advances in manufacturing processes, such as chemical vapor deposition, have made it possible to produce high-quality diamond substrates at scale, further enhancing their accessibility and sustainability.

Challenges and Future Directions

Despite their many advantages, the widespread adoption of diamond substrates is not without challenges. One of the primary barriers is cost. The production of synthetic diamond substrates requires specialized equipment and processes, making them more expensive than traditional materials. However, ongoing research and development efforts are focused on reducing production costs and improving scalability.

Another challenge is the integration of diamond substrates into existing technologies. While their unique properties offer significant advantages, they also require the development of new manufacturing techniques and device architectures to fully exploit their potential.

Looking ahead, the future of diamond substrates is bright. As research continues to advance, we can expect to see even more innovative applications emerge. For example, diamond substrates could play a pivotal role in the development of next-generation energy systems, such as high-efficiency solar cells and advanced battery technologies. They may also enable breakthroughs in fields like space exploration and nanotechnology, where their exceptional properties are particularly valuable.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness