Why Do Architects and Contractors Depend on Accurate Millwork Shop Drawings?

In the world of construction and interior architecture, precision is paramount. Among the many detailed components that bring a building project to life, millwork—custom woodwork such as cabinetry, moldings, panels, and trim—plays a crucial role in both functionality and aesthetics.

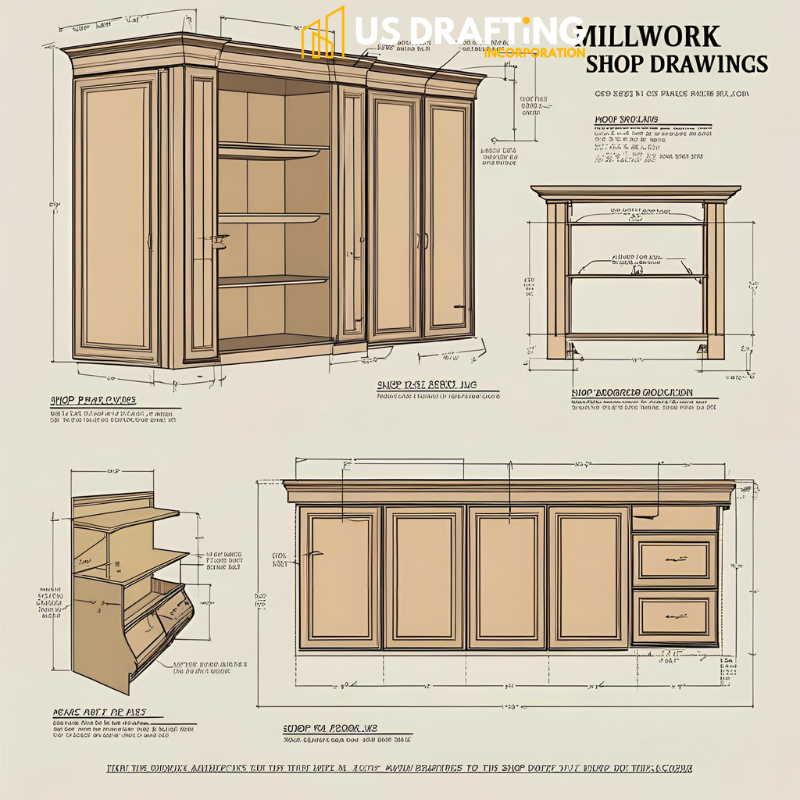

For architects and contractors, accurate millwork shop drawings are essential tools that bridge the gap between design intent and final execution. These detailed drawings provide exact specifications, dimensions, materials, and installation guidelines, ensuring that every piece fits seamlessly within the larger architectural framework.

Without them, projects are susceptible to costly errors, delays, and miscommunications. As such, millwork shop drawings are not just technical documents—they are vital instruments of collaboration, coordination, and quality assurance on any construction site.

What Are Millwork Shop Drawings?

Millwork shop drawings are detailed plans that show how custom woodwork items will be made and installed. These items can include cabinets, doors, shelves, moldings, trim, and other wooden features in a building. The drawings are made by millwork companies or drafters before the actual work begins.

These drawings are very important in construction and interior design. They help everyone understand what the final product will look like. Millwork shop drawings include exact sizes, materials, shapes, and where each piece will go. They also show how different parts will be put together and how they will fit into the space.

Architects and designers often give a general idea of what they want. Then, the millwork company creates shop drawings based on that idea. These drawings are sent back to the architect, designer, or client for approval before anything is built. This helps avoid mistakes and saves time and money.

Millwork shop drawings are also used by workers in the shop and on the job site. They use the drawings as a guide to make and install the wood pieces correctly. The drawings must be clear and accurate so the finished product matches the design perfectly.

In short, millwork shop drawings are like a map that helps turn design ideas into real woodwork. They play a key role in making sure everything fits well, looks good, and works as planned in a building project

Why Accuracy Matters: Key Reasons

Accuracy means being correct and exact. It is very important in our daily lives, school, work, and even in small tasks. Being accurate helps people trust us and believe in what we say or do. When we give correct information, others can make better decisions.

In school, students need accuracy in their homework and tests. If answers are wrong, it affects their learning and grades. In work, accuracy is even more important. For example, if a doctor is not accurate, it can harm a patient. If a builder is not accurate, a house might not be safe. So, being accurate can keep people safe and healthy.

Accuracy also saves time and money. When something is done right the first time, we don’t need to fix mistakes. This helps us work faster and better. Mistakes can cost a lot, especially in business or big projects.

Clear and accurate communication is also important. If we send a wrong message or give wrong details, it can lead to confusion and problems. Accuracy helps people understand each other and work well together.

In today’s world, with so much information online, accuracy matters even more. Sharing false or wrong information can mislead people. It’s always good to check facts before sharing them.

Benefits for Stakeholders of Millwork Shop Drawings

Millwork shop drawings are detailed plans that show how custom woodwork items like cabinets, doors, panels, and trim will be made and installed. These drawings are helpful to all the people involved in a construction or renovation project.

For architects and designers, shop drawings ensure their ideas are clearly understood. They can check the drawings to make sure the design looks right and matches the overall plan. This helps avoid mistakes and saves time.

For contractors and builders, shop drawings give clear instructions. They show the exact size, shape, and materials needed. This helps the work move smoothly and reduces delays. With detailed drawings, everyone knows what to expect, and the risk of rework is lower.

For millwork fabricators, these drawings are like a roadmap. They help workers create the wood pieces accurately and quickly. When fabricators follow clear drawings, the finished product fits perfectly on-site.

Clients and project owners also benefit. With shop drawings, they can see what the final product will look like before it is made. This helps them feel more confident about the project. If they want changes, it’s easier to make them early in the process.

Overall, millwork shop drawings help all stakeholders work better together. They improve communication, reduce errors, and make the project more efficient. With everyone on the same page, the final result is more likely to meet expectations in quality, time, and cost.

Best Practices for Producing Accurate Millwork Shop Drawings

Creating accurate millwork shop drawings is very important in the construction and woodworking industry. These drawings show detailed designs for cabinets, panels, trims, and other custom woodwork. To make sure the work is correct and done on time, follow these best practices.

1. Understand the Design Intent:

Start by carefully reading the architectural drawings and design specifications. Know what the architect or designer wants. Ask questions if anything is unclear.

2. Use Standard Templates:

Using pre-made templates saves time and helps keep drawings consistent. Make sure to include title blocks, revision history, and proper labels on each page.

3. Include All Details:

Add all the needed information like dimensions, materials, finishes, hardware, and joinery methods. The more details you include, the fewer mistakes will happen during production.

4. Double-Check Measurements:

Always check your dimensions more than once. A small mistake can lead to big delays and added costs.

5. Follow Industry Standards:

Use common symbols and drawing styles that others in the industry understand. This makes it easier for teams to read and use the drawings.

6. Review and Approve:

Before sending the drawings for production, have them reviewed by the project manager or architect. Getting approval helps avoid rework.

7. Keep Everything Organized:

Name files clearly and keep a system for version control. This helps the team know which drawing is the most current.

The End Note

Accurate millwork shop drawings are essential to the success of any construction or interior design project. They serve as a critical link between the architect’s vision and the final product, ensuring that every custom woodwork element is crafted and installed correctly.

These drawings help prevent costly mistakes, save time, and improve communication among all project stakeholders from designers and contractors to fabricators and clients. By following best practices such as understanding design intent, including complete details, and maintaining quality control through reviews and approvals, teams can ensure that their millwork components are both functional and visually cohesive.

In the end, accurate shop drawings are not just technical blueprints they are vital tools that bring design concepts to life with precision and professionalism.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness