Bulk Container Packaging vs. Traditional Methods: A Comparative Analysis

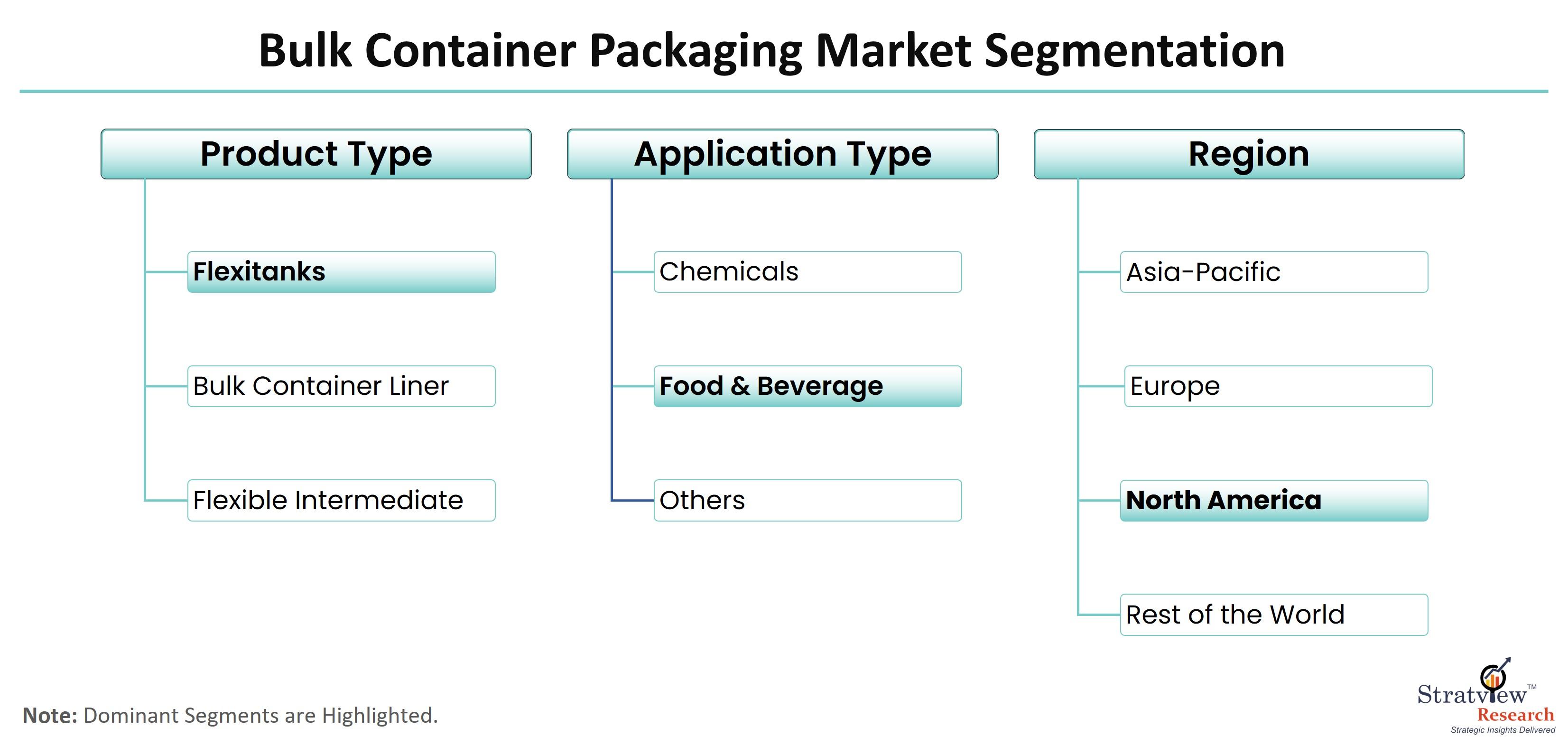

According to Stratview Research, the bulk container packaging market was estimated at USD 3.5 billion in 2021 and is likely to grow at a CAGR of 9.37% during 2022-2028 to reach USD 6.59 billion in 2028.

Packaging plays a pivotal role in the modern supply chain, impacting everything from transportation costs to environmental sustainability. When it comes to packaging solutions, businesses often face a critical choice between bulk container packaging and traditional methods. In this comparative analysis, we will delve into the pros and cons of each approach to help businesses make informed decisions about their packaging needs.

Bulk Container Packaging: The Efficiency Champion

High Capacity: Bulk container packaging solutions are designed to carry large quantities of goods efficiently. They maximize cargo capacity, reducing the number of trips required for transportation.

Streamlined Handling: Bulk containers often feature ergonomic design elements such as integrated handles and forklift pockets. This simplifies loading and unloading processes, reducing labor costs and minimizing the risk of accidents.

Space Optimization: When empty, bulk containers can be stacked or nested, optimizing storage space. This feature is especially valuable in warehouses with limited storage capacity.

Reduced Packaging Waste: By using bulk containers, businesses can significantly reduce the need for disposable packaging materials like bags, boxes, and drums. This reduction in packaging waste aligns with sustainability goals and reduces waste disposal costs.

Cons:

Initial Investment: Acquiring bulk containers may require a higher initial investment compared to traditional packaging materials. However, the long-term cost savings often offset this initial expense.

Space Requirements: Businesses need adequate storage space for bulk containers when they are not in use. This may pose a challenge for smaller facilities with limited storage capacity.

Traditional Methods: Tried and Tested

Pros:

Lower Initial Cost: Traditional packaging materials like cardboard boxes, bags, and drums are generally more affordable upfront. This can be appealing for budget-conscious businesses.

Familiarity: Traditional packaging methods are well-understood and familiar to workers and logistics personnel. This can reduce the learning curve and potential errors during handling.

Versatility: Traditional packaging materials can be suitable for a wide range of products and applications, offering flexibility in packaging choices.

Cons:

Limited Capacity: Traditional packaging materials may have limited capacity, which can lead to increased transportation costs due to more trips required for bulk goods.

Packaging Waste: Traditional packaging methods often generate a substantial amount of waste, including cardboard, plastics, and other materials. Disposing of this waste can be costly and environmentally detrimental.

Handling Challenges: Traditional packaging materials may require additional handling steps, such as repackaging at distribution centers. This adds complexity and labor costs to the supply chain.

Comparative Analysis: Efficiency and Sustainability

Efficiency: Bulk container packaging clearly excels in efficiency. Its high capacity and streamlined handling result in reduced transportation costs and improved supply chain efficiency. Traditional methods, with their limited capacity and potential for repackaging, can lead to inefficiencies, especially for businesses dealing with bulk goods.

Sustainability: Sustainability has become a critical consideration in packaging. Bulk container packaging aligns well with sustainability goals. It reduces packaging waste, lowers carbon emissions through optimized transportation, and often incorporates reusable and recyclable materials. Traditional packaging methods generate more waste and are less environmentally friendly.

Conclusion: The Right Choice for Your Business

The choice between bulk container packaging and traditional methods depends on various factors, including the type of products, budget, storage space, and sustainability objectives. While traditional methods may offer cost advantages upfront, businesses must consider the long-term costs, environmental impact, and logistical efficiency associated with their choice.

For businesses seeking to optimize supply chains, reduce environmental impact, and align with sustainability goals, bulk container packaging is often the preferred choice. It offers the efficiency needed in modern logistics while contributing to a more sustainable future. However, the decision ultimately rests on the specific needs and priorities of each business, highlighting the importance of a well-informed and tailored packaging strategy.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness