Understanding the Monoethylene Glycol Market: Key Drivers and Trends

Monoethylene glycol is a vital chemical compound with diverse industrial applications, primarily known for its use in the production of polyester fibers and resins. As a crucial component in the chemical industry, the monoethylene glycol market is influenced by several key drivers and trends that shape its dynamics and growth prospects.

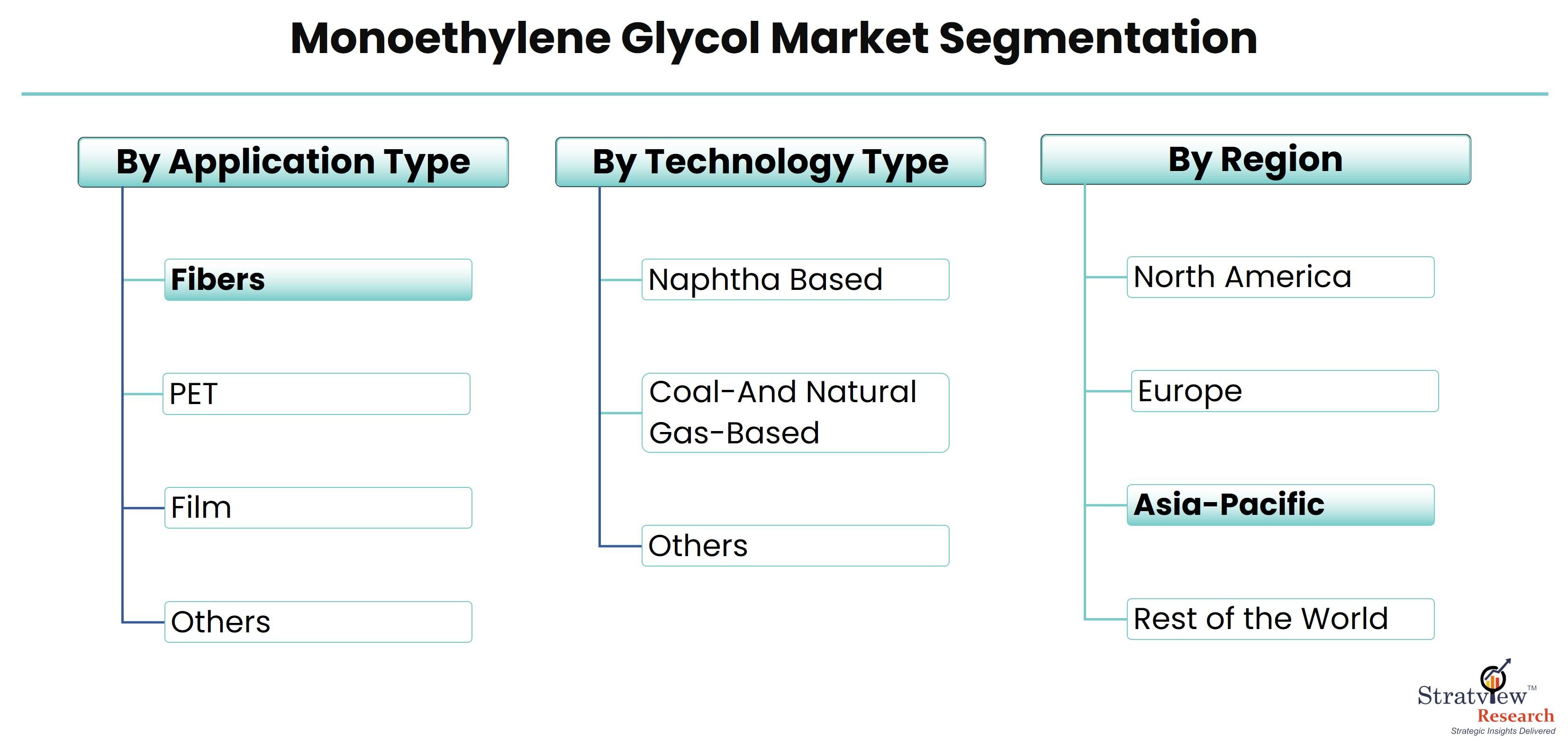

According to Stratview Research, the monoethylene glycol market was estimated at USD 5.77 billion in 2022 and is likely to grow at a CAGR of 3.52% during 2023-2028 to reach USD 7.1 billion in 2028.

1. Polyester Production Dominance

The primary driver of the monoethylene glycol market is its extensive use in the production of polyester fibers and resins. Monoethylene glycol is a key raw material in the manufacturing of polyethylene terephthalate (PET), which is widely used in textiles, packaging, bottles, and other consumer goods. The demand for polyester continues to grow globally, driven by urbanization, rising disposable incomes, and the expanding middle class in emerging economies.

2. Growth in PET Packaging

The packaging industry is a major consumer of PET, driving demand for monoethylene glycol. PET's properties, such as transparency, lightweight, and recyclability, make it ideal for food and beverage packaging. With increasing concerns about environmental sustainability, PET's recyclability has further boosted its demand, thus driving the monoethylene glycol market.

3. Economic Development and Urbanization

Economic development and urbanization in emerging markets play a significant role in the growth of the monoethylene glycol market. Rapid industrialization and urban expansion increase the demand for textiles, plastics, and other consumer goods, all of which rely heavily on polyester derived from monoethylene glycol. Countries in Asia-Pacific, particularly China and India, are major contributors to the market due to their manufacturing capabilities and growing consumer markets.

4. Technological Advancements

Technological advancements in monoethylene glycol production processes contribute to the market's growth by improving efficiency and reducing costs. Innovations in catalysts, process intensification, and sustainability practices are enhancing the production capacity and environmental footprint of monoethylene glycol manufacturing facilities. These advancements not only support market expansion but also address environmental concerns associated with chemical production.

5. Sustainability Initiatives

Environmental sustainability is increasingly influencing the monoethylene glycol market. Manufacturers are focusing on reducing carbon emissions, water consumption, and waste generation in monoethylene glycol production. The development of bio-based monoethylene glycol, derived from renewable feedstocks such as sugarcane or biomass, is gaining traction as companies seek to reduce dependence on fossil fuels and lower their environmental impact.

6. Market Challenges

Despite its growth prospects, the monoethylene glycol market faces challenges such as fluctuating raw material prices, regulatory constraints, and geopolitical tensions affecting trade dynamics. Price volatility of ethylene, a primary feedstock for monoethylene glycol production, can impact profit margins and investment decisions in the industry.

In conclusion, the monoethylene glycol market is driven by its integral role in polyester production, growth in PET packaging, economic development, technological advancements, sustainability initiatives, and various market challenges. As global demand for polyester continues to rise and sustainability becomes more critical, the monoethylene glycol market is poised for continued growth and innovation, shaping the future of the chemical industry.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness