Key Factors Shaping the PCB Encapsulation Market: Drivers and Challenges

The PCB encapsulation market is a critical component of the electronics industry, where the protection of PCBs from external damage, moisture, and environmental stress is paramount. As the demand for more advanced electronics continues to rise, encapsulation materials are evolving to offer greater protection and functionality. However, the market faces several challenges, including material costs and regulatory pressures.

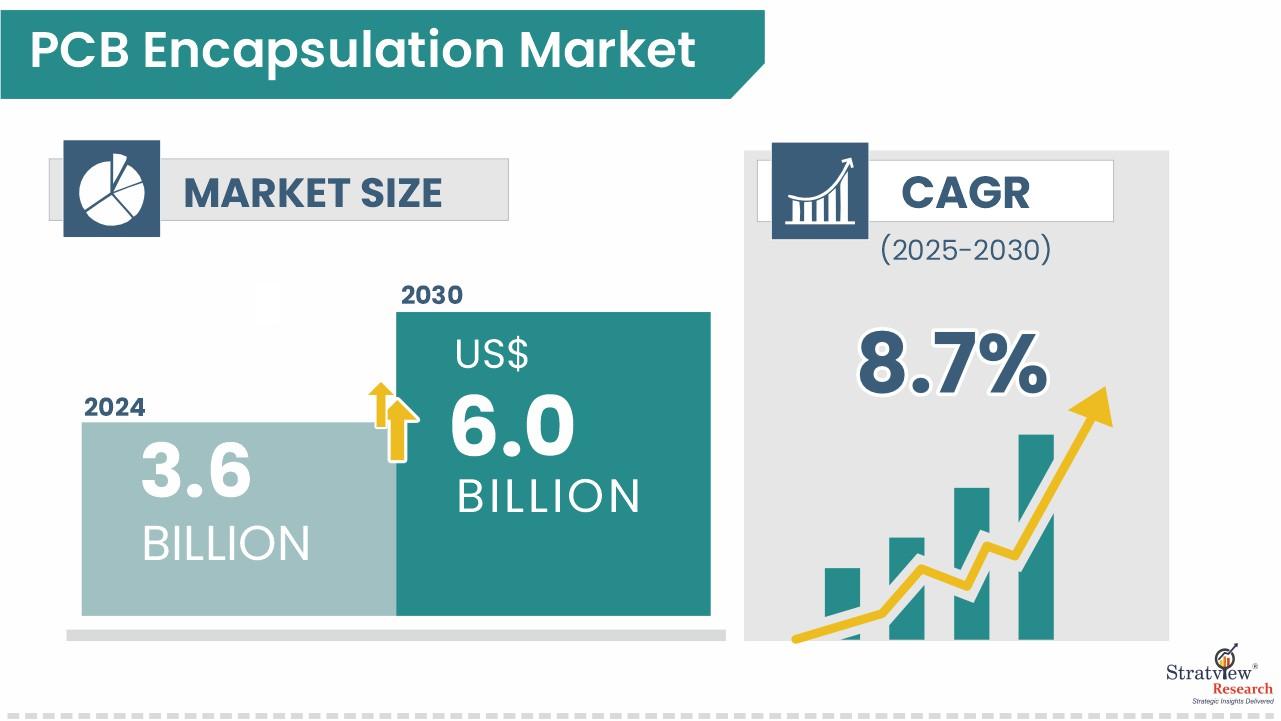

According to Stratview Research, the PCB encapsulation market was estimated at USD 3.6 billion in 2024 and is likely to grow at a CAGR of 8.7% during 2025-2030 to reach USD 6.0 billion in 2030.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/4057/pcb-encapsulation-market.html#form

Drivers:

- Miniaturization and Performance Demands in Electronics: As electronics become smaller and more complex, the need for high-performance encapsulation materials that can protect delicate PCBs in tight spaces is increasing.

- High Demand in Emerging Technologies: The rise of technologies such as 5G, AI, and IoT requires PCBs that can handle greater speeds and more advanced functions, necessitating the development of specialized encapsulants.

- Automotive Electronics Demand: The shift towards electric vehicles and the growing reliance on electronics in automotive systems, such as ADAS and infotainment, is fueling demand for reliable PCB encapsulation solutions.

Trends:

- Increase in Smart Devices: The proliferation of smart devices and wearable technology is driving innovation in PCB encapsulation materials, as these products require compact, efficient, and durable PCBs.

- Use of Flexible Encapsulation Materials: As flexible PCBs gain traction in wearable electronics and other consumer devices, encapsulation materials are becoming more flexible to accommodate these designs.

- R&D in High-Temperature Resins: As industries such as aerospace and automotive demand higher heat tolerance, there is a growing trend toward developing encapsulants that can withstand extreme temperatures.

Challenges:

- Cost of High-Performance Encapsulation Materials: Advanced encapsulation materials that offer superior protection and performance are often more expensive, limiting their adoption in budget-conscious applications.

- Environmental and Recycling Issues: The lack of recycling options for encapsulated PCBs remains a significant challenge. Encapsulation materials, especially epoxies and silicones, can be difficult to recycle.

- Material Compatibility with New Technologies: As new technologies emerge, ensuring the compatibility of encapsulation materials with these advancements remains a challenge for manufacturers.

Opportunities:

- Advanced Materials for Automotive Electronics: The increasing complexity of automotive electronics presents opportunities for advanced PCB encapsulants that can withstand harsh environments and extreme temperatures.

- Smart Packaging Solutions: With the rise of IoT and smart packaging in industries like logistics and healthcare, there is an opportunity to develop PCB encapsulants that support smart sensors and components.

- Global Expansion in Emerging Markets: The growing industrialization and consumer electronics production in emerging markets like Asia-Pacific offer significant opportunities for the PCB encapsulation market.

Conclusion:

The PCB encapsulation market is evolving rapidly to meet the demands of modern electronics. Although challenges such as cost, performance trade-offs, and recycling remain, significant opportunities exist in automotive, emerging technologies, and smart devices.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness