Revolutionizing Tomorrow: How Industrial Robotics Is Reshaping Manufacturing Forever

In today's rapidly evolving technological landscape, Industrial Robotics stands at the forefront of a new industrial revolution. What once was science fiction is now a standard in modern factories, logistics hubs, and high-tech warehouses. These robotic systems are not only increasing productivity but also transforming the very foundation of how industries operate worldwide.

The Rise of Industrial Robotics

Over the past decade, we’ve witnessed a massive surge in the development and adoption of Industrial Robotics. This growth is driven by advances in artificial intelligence, machine learning, sensor technology, and automation software. Companies are under increasing pressure to meet higher demands, improve safety, reduce costs, and enhance efficiency—all goals that industrial robots are perfectly equipped to meet.

Unlike traditional manual labor or even legacy automated machines, industrial robots offer dynamic, adaptive solutions. They can be reprogrammed, upgraded, and optimized continuously, making them far more flexible and scalable. Whether it’s assembling components, welding, painting, or packaging, robotic systems perform with unmatched speed and accuracy.

Efficiency Meets Precision

One of the biggest advantages of Industrial Robotics is precision. Robots don’t get tired, make fewer errors, and can operate 24/7 without breaks. In industries like automotive, electronics, and pharmaceuticals, this means reduced waste, improved product quality, and faster time-to-market.

For example, automotive manufacturers now use robotic arms to complete intricate tasks like installing windshields or welding steel frames—tasks that require extreme accuracy. The result is not just better-built cars, but safer and more cost-effective production lines.

A New Era of Workforce Collaboration

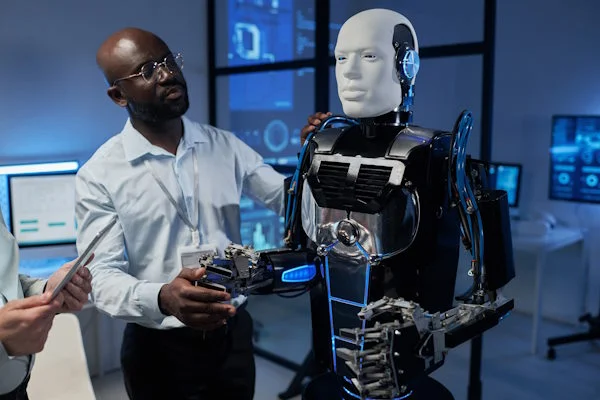

Contrary to the myth that robots are replacing humans, the truth is more nuanced. Industrial Robotics is enhancing the human workforce by taking over repetitive, dangerous, or physically taxing jobs. This allows human workers to focus on tasks that require creativity, decision-making, and problem-solving.

Collaborative robots—or "cobots"—are designed to work alongside humans safely. These intelligent systems come equipped with sensors and algorithms that detect and adapt to human presence, enabling a new form of man-machine teamwork on the factory floor.

Cost Savings and Scalability

Although the initial investment in Industrial Robotics may seem high, the long-term savings are substantial. Robots reduce downtime, minimize defects, and increase throughput, all of which contribute to higher profits. Additionally, businesses can scale operations quickly by simply adding more robotic units or reprogramming existing ones for new tasks.

Small and medium-sized enterprises are also jumping on board, thanks to the decreasing cost of robotic technology and the rise of robotics-as-a-service (RaaS) models. Now, even smaller manufacturers can benefit from automation without massive upfront costs.

The Future Is Automated and Intelligent

Looking ahead, Industrial Robotics is set to become even more intelligent and integrated. Future developments will focus on autonomous decision-making, AI-driven diagnostics, predictive maintenance, and advanced human-robot interaction. These improvements will push the boundaries of what's possible in industrial automation.

In conclusion, Industrial Robotics is not just a trend—it’s the future of manufacturing. From enhancing productivity and safety to driving innovation and growth, these smart machines are transforming industries in ways we never thought possible. Embracing robotics today means staying competitive tomorrow.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness