Anchoring Reliability: Material Advancements in Engine Sealing Systems

Marine environments are among the harshest for mechanical systems. Seals used in recreational boat engines must endure high pressure, salt, UV exposure, and fluctuating temperatures. Recent advances in material science are helping address these challenges.

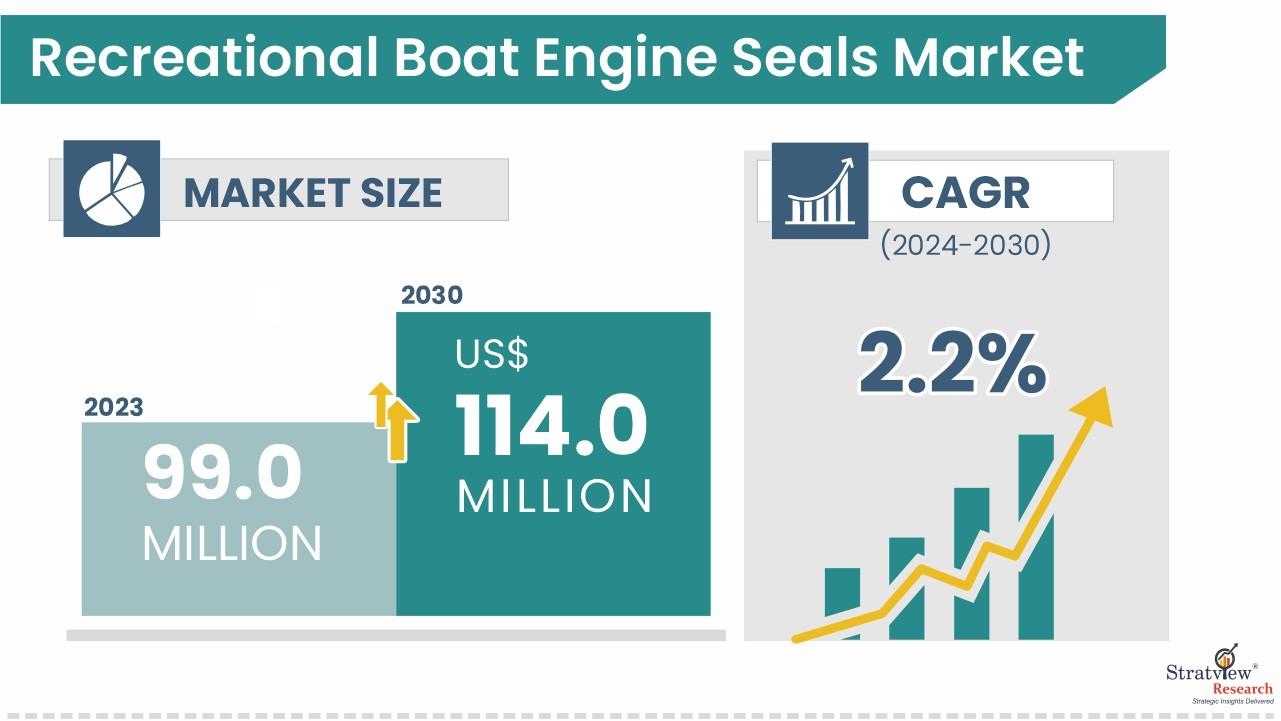

According to Stratview Research, the recreational boat engine seals market size was USD 99.0 million in 2023 and is likely to grow at a healthy CAGR of 2.2% during 2024-2030 to reach USD 114 million in 2030.

Request a sample report to preview our in-depth analysis.

Drivers

- Demand for Corrosion-Resistant Seals

- Need for Compact and Lightweight Sealing Systems

- Growth in High-Torque Engines for Sports and Utility Boats

Challenges

- Balancing Cost and Durability: Premium materials often come at higher prices, limiting their use in entry-level boats.

- Limited Recycling Options: End-of-life disposal of marine elastomers remains an issue.

Trends

- Use of Viton, Silicone, and Teflon-Based Compounds

- Nanotechnology to Improve Seal Surfaces

- Blending Elastomers with Recycled Marine Plastics

Opportunities

- Brand Differentiation via Material Innovation

- Patent-Protected Designs for OEM Partnerships

- Seals for Electric Boat Motors with Specialized Cooling Requirements

Conclusion

Material science is proving to be a game-changer in the engine seals market. Companies that focus on high-performance, eco-conscious materials stand to gain both consumer trust and regulatory approval.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness