Soft Power: Elastomeric Isolators in Modern Aerospace Applications

In aerospace engineering, vibration and shock can significantly impact safety and performance. Elastomeric isolators, made from high-grade rubber compounds, provide the necessary damping to safeguard structures and electronics in aircraft and spacecraft. Their small size belies their critical role in flight operations.

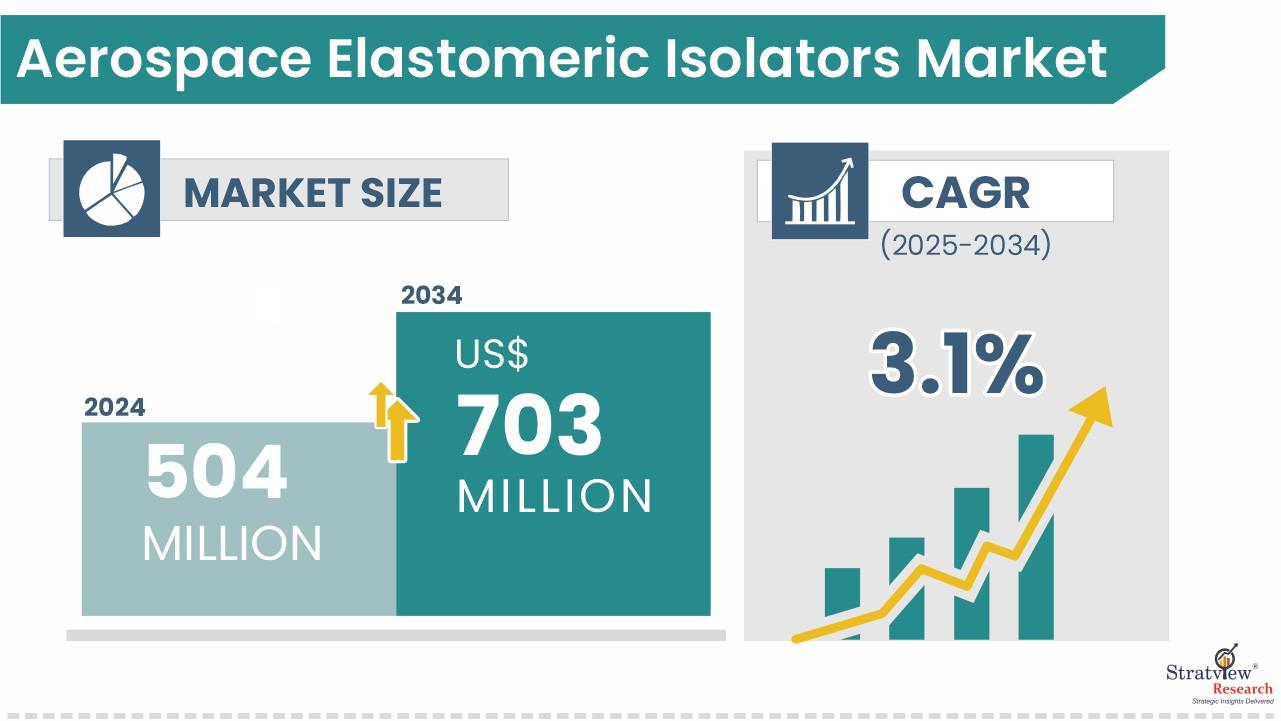

According to Stratview Research, the aerospace elastomeric isolators market was estimated at USD 504 million in 2024 and is likely to grow at a CAGR of 3.1% during 2025-2034 to reach USD 703 million in 2034.

Request a sample report to preview our in-depth analysis.

https://stratviewresearch.com/Request-Sample/4084/aerospace-elastomeric-isolators-market.html#form

Drivers

- Electronics Protection: Preventing vibration damage to sensitive avionics.

- Growing UAV Market: Drones and unmanned systems also require vibration control solutions.

- Retrofitting Programs: Upgrading older aircraft with modern isolation systems.

- Expansion of MRO Services: Maintenance operations drive aftermarket isolator demand.

Challenges

- Service Life Limitations: Elastomer fatigue over time necessitates replacements.

- Complex Testing Needs: Performance validation under multi-axis loads is demanding.

- Global Supply Chain Risks: Dependence on specialized rubber suppliers.

Trends

- Nano-Filler Reinforcement: Nanomaterials used to enhance elastomer strength.

- Temperature-Resistant Solutions: Products designed for extreme cold at high altitude.

- Rapid Replacement Systems: Quick-swap isolators to reduce downtime.

Conclusion

As aerospace platforms evolve, isolators must meet higher performance standards. Market leaders will focus on durability, lightweighting, and integration with advanced monitoring systems.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness