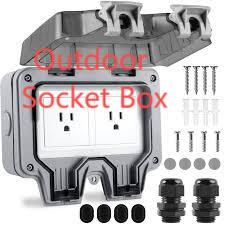

Nante Field Checklist — Outdoor Socket Box Commissioning and Seasonal Inspection Steps

Specifiers and installers commonly begin outdoor power projects by choosing an Outdoor Socket Box , and that early choice quickly determines whether the installation will be low-maintenance or a recurring liability. Proper selection, careful siting, and a practical maintenance rhythm turn a simple enclosure into a long-lived asset rather than a frequent headache.

Assess Site Conditions First

Begin with an honest climate and exposure survey. Consider prevailing winds, salt spray, UV index, freeze–thaw cycles, and the local incidence of landscape irrigation or vehicle spray. Identify mechanical risks such as impact or vandalism and note access constraints for maintenance crews. Matching the enclosure’s substrate, coating, and ingress rating to these realities prevents expensive retrofits.

Materials and Construction That Resist the Elements

Choose substrates and finishes that fight corrosion and UV degradation. Stainless steel, powder-coated aluminium, and UV-stabilized polymers each have roles depending on site chemistry and temperature ranges. Pay attention to fastener metallurgy and gasketing materials; a poorly chosen screw or elastomer negates an otherwise rugged shell. Door geometry—deep overlaps and continuous gaskets—forces water to run off rather than find a path in.

Cable Entry, Sealing, and Internal Protection

Effective cable entry strategy combines gravity, compression, and abrasion protection. Orient glands downward, use purpose-sized compression fittings, and protect jackets with formed entry plates where multiple conductors arrive. Internally, raise mounting plates to keep devices above incidental pooling and use rounded knockouts to avoid jacket pinch points. Consider conduit transitions for exposed runs to reduce mechanical wear and preserve seals.

Layout for Serviceability and Thermal Management

Design the interior to minimize time spent exposed to the weather. Segregate control wiring from power conductors, maintain generous cable bend radii, and leave working clearances above thermal devices to permit convection cooling. Place neutral and grounding terminals where they’re accessible without reaching over live parts. Durable, contrast-rich labels and an inside-door directory speed troubleshooting and cut technician exposure during poor light or rain.

Preventing Condensation and Managing Heat (Schneider Solutions)

Condensation control protects electronics from silent failure. Passive pressure-equalizing vents with hydrophobic membranes allow safe air exchange while blocking water. In hot sites, sunshades, reflective finishes, or strategic placement in partial shade reduce internal heat stress. For retrofit venting, surge protection, and thermal modules, review vendor offerings—brands such as Schneider provide purpose-built accessories that integrate with many common enclosure forms.

Installation Details That Matter

Small installation choices produce big operational differences. Mount units above local splash lines, avoid direct sprinkler exposure, and use stand-off backplates to permit airflow behind the enclosure. Size glands to the real cable diameter, not an estimate, and torque lugs to specification to avoid loose or damaged connections. Photograph the completed installation and save the images with a concise as-built note for future troubleshooting.

A Practical Maintenance Rhythm

Adopt a seasonal checklist: inspect gasket condition, confirm latch compression, clear drains and weeps, and note any UV chalking or paint degradation. Replace compromised seals promptly and keep a compact spares kit—glands, a spare gasket, common fasteners—so field repairs don’t wait on supply. Log findings with dates and photos so gradual trends are visible before failures occur.

Procurement, Documentation, and End-of-Life Planning

Standardize on a small set of form factors and hardware to simplify spares and training. Require batch test documentation for critical applications and insist on traceability for essential components. Keep as-built schematics and photos with the site record to accelerate fault diagnosis. When units retire, segregate metals and boards for responsible recycling and disposal.

Bringing It All Together

Reliable exterior power depends on linking specification, installation discipline, and a simple maintenance program. Thoughtful choices about materials, entry details, internal layout, and inspection cadence produce enclosures that stay quiet, safe, and serviceable for many years. For product comparisons, accessories, and detailed configuration options, visit www.nante.com/product/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness