A Guide to the Versatile ABS Plastic Sheet

The world of material science develops continuously, new compounds and composites are being developed to meet modern production and design requirements. Among them, acrylonitril the beetroot board, often known as ABS, separates as a real work. This thermoplastic polymer is a ubiquitous appearance, which exists everything from children's toys to sophisticated car components. Its popularity is not an accident; The unique mixture of properties near it makes it an incredibly adaptable and cost -effective option for a wide range of applications. This guide will be engrossed by the properties of ABS plastic, to find out why they have become an indispensable material for the many industries.

The Genesis and Composition of ABS

ABS is not a single polymer, but a mixture of a fellow poles or three different monomers: acrylonitril, butadin and styrin. 150 gsm geotextile provides significant cruelty and influence resistance, especially at low temperatures. Finally, Styin adds a light finish, light in stiffness and processing. The exact ratio of these three monomers can be adjusted to create different ABS characters, each with a slightly different set of properties that fits a specific application. This ability to "fine -tune" the material is an important cause of versatility. Unlike many other plastic that is hard and crispy, ABS creates a remarkable balance between strength, flexibility and resistance to effect.

The Remarkable Properties of ABS Sheets

This is the one that makes ABS ideal for products that require accessories, drops and normal wear and tears, such as goods, protective molding and sports equipment. Even at low temperatures, where many plastic get brittle, ABS retains its cruelty. Another main function is the excellent engine power. ABS can easily be cut, drilled, anchored and seen using standard units. This makes it a favorite of hobbies, prototypes and manufacturers, who have to create complex designs or custom parts.

In addition, ABS has good dimensional stability, which means it keeps the shape well under different conditions. It is also resistant to many chemicals, including acids, alkalis and oil, which makes it suitable for use in the environment where it can be brought into contact with such substances. Although it does not have the same chemical resistance to some more special polymers, its broad -spectrum flexibility is higher than sufficient for most common applications. The surface of the ABS sheet is also receptive to painting, printing and gluing, which allows a wide range of finishing options. The matte or light surface is visually attractive and can be further improved.

Applications of ABS Plastic

One of the most common uses is in motor vehicles, where it is used to make dashboard components, trims and even wheel covers. The light but durable nature contributes to fuel efficiency, and provides a strong, aesthetically pleasant part. In the electronics field, ABS plastic sheet is the contents of computer houses, keyboard keys and choices for different electronic cabinets. The capacity is cast to complex shapes and its insulation properties are invaluable here.

In addition to these famous examples, the ABS sheets find the way in the amount of other products. Medical equipment, such as units for housing and diagnostic machines, often uses ABS due to its slightly clean surface and durability. In the construction industry there are in pipe fittings and decorative panels. Even in agriculture and landscaping, materials such as 150 GSM lands are often used in combination with plastic materials to handle soil erosion and drainage, indicating how a variety of materials are used to achieve desired results.

Manufacturing and Availability of ABS Sheets

The sheet is then cooled and cut in size. This process is very effective and allows for the production of large amounts of sheets of frequent quality. The ability to produce sheets by different thicknesses, to create vacuum from very thin meter, thick for structural applications, improves its utility.

When you pick up ABS, the supplier's reputation and the quality of their products are necessary to consider. Companies such as Singhal Industrie's Private Limited have established themselves as high -quality reliable manufacturers including ABS Their expertise in production ensures that the final product meets the specifications required for different applications. It is also important to assess the environmental impact of the material. While ABS is a petroleum -based plastic, it is heavily recycled, and many manufacturers now involve recycled materials in their production processes, reduced waste and require virgin materials.

The Case for Sustainability and Recyclability

As the world focuses rapidly on permanent practice, recycling of materials becomes an important factor. ABS plastic is fully recycled. This closed loop system is important for a more circular economy. Many companies are now making a conscious effort to use recycled ABS in their products, and appeals to environmentally conscious consumers and rules.

The Future of ABS and Its Continued Relevance

The future she looks confident with its characteristics even better for the research and development. Researchers are looking for new mixtures and composites, such as ABS with fiberglass or carbon fiber reinforcement, to create materials with more power-to-war conditions. There is also pressure to develop bio -based ABS using Akshaya Feedstox to reduce the dependence on petroleum. Since adjacent production (3D printing) becomes more widespread, ABS sheets Singhal Industries Pvt Ltd filaments are a popular alternative because of their strength and printability, which allows new markets and applications to completely.

Conclusion

In the radius of modern plastic out for its extraordinary versatility performance. The unique mixture of acrylonitril, beets and the steering provide it a victorious combination of strength, effect resistance and durability creates an ideal material for everything from everyday consumables to complex industrial components. The simple plastic plate for ABS can be manufactured, mechanized and recycled from, it can be advanced as a very practical and durable alternative. As industries continue to be renewed, .

Frequently Asked Questions

Question: Is ABS plastic safe for food contact?

Answer: In its pure form, ABS is generally considered non-toxic, and certain grades can be approved by regulatory bodies like the FDA for food-contact applications. However, not all ABS sheets are food-safe. The safety for food contact depends on the specific grade of ABS and any additives used during its manufacture.

Question: How does ABS compare to other common plastics like PVC or polycarbonate?

Answer: ABS, PVC, and polycarbonate each have distinct properties. ABS offers a good balance of impact resistance and strength at a lower cost than polycarbonate. Polycarbonate is significantly stronger and more impact-resistant, making it suitable for applications like bulletproof glass or safety shields, but it is also more expensive.

Question: Can ABS plastic sheets be used for outdoor applications?

Answer: While ABS is durable, it is not ideal for prolonged outdoor use without special treatment. Untreated ABS is susceptible to UV degradation, which can cause the material to become brittle, lose color, and crack over time.

Question: Who is the largest supplier of ABS Plastic Sheet?

Answer: The largest suppliers of ABS Plastic Sheets globally include companies like INEOS Styrolution, Chi Mei Corporation, and Trinseo. In India, Singhal Industries Private Limited is a well-known supplier.

Question: Who is the largest exporter of ABS Plastic Sheet?

Answer: According to recent trade data, China is the largest exporter of ABS Plastic Sheet, followed by countries like South Korea and Vietnam Singhal Industries Private Limited.

Question: Who is the largest manufacturer of ABS Plastic Sheet?

Answer: Major global manufacturers of ABS Plastic Sheet include LG Chem, SABIC, and Formosa Plastics Corporation. Singhal Industries Private Limited is a notable manufacturer in the Indian market.

Question: What are the primary uses of ABS Plastic Sheet?

Answer: ABS Plastic Sheet is a versatile material used in various applications, including automotive parts, luggage, consumer goods, and architectural modeling.

Question: Is ABS Plastic Sheet recyclable?

Answer: Yes, ABS Plastic Sheet is a thermoplastic and can be recycled, which is a key characteristic of many plastic materials.

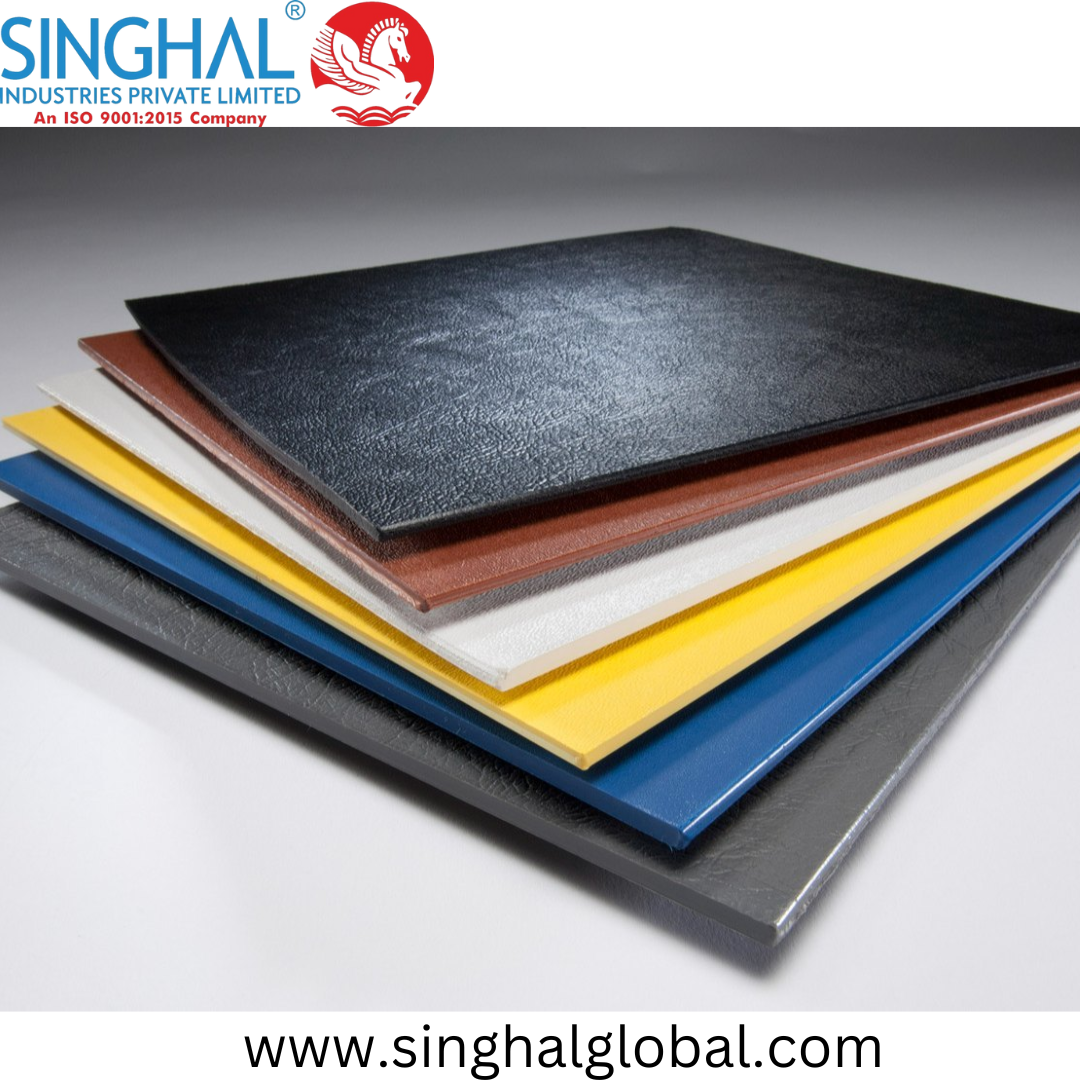

Question: What are the different grades of ABS Plastic Sheet available?

Answer: ABS plastic sheets come in various grades, such as engineering grade and vacuum-forming grade, with options for different thicknesses, colors, and finishes.

Question: How is ABS Plastic Sheet manufactured?

Answer: ABS Plastic Sheet is typically manufactured through an extrusion process, where the raw material is melted and pushed through a die to form the desired sheet shape.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness