Liquid Silicone Rubber Market: Expanding Applications Across Industries

Liquid silicone rubber (LSR) has become one of the most versatile materials in modern manufacturing, thanks to its unique combination of flexibility, durability, and biocompatibility. Unlike traditional elastomers, LSR is processed through injection molding, enabling high-volume production of complex parts with consistent quality. With applications spanning automotive, healthcare, consumer electronics, and industrial goods, the liquid silicone rubber market is gaining traction as industries demand high-performance materials for safety-critical and precision-engineered products.

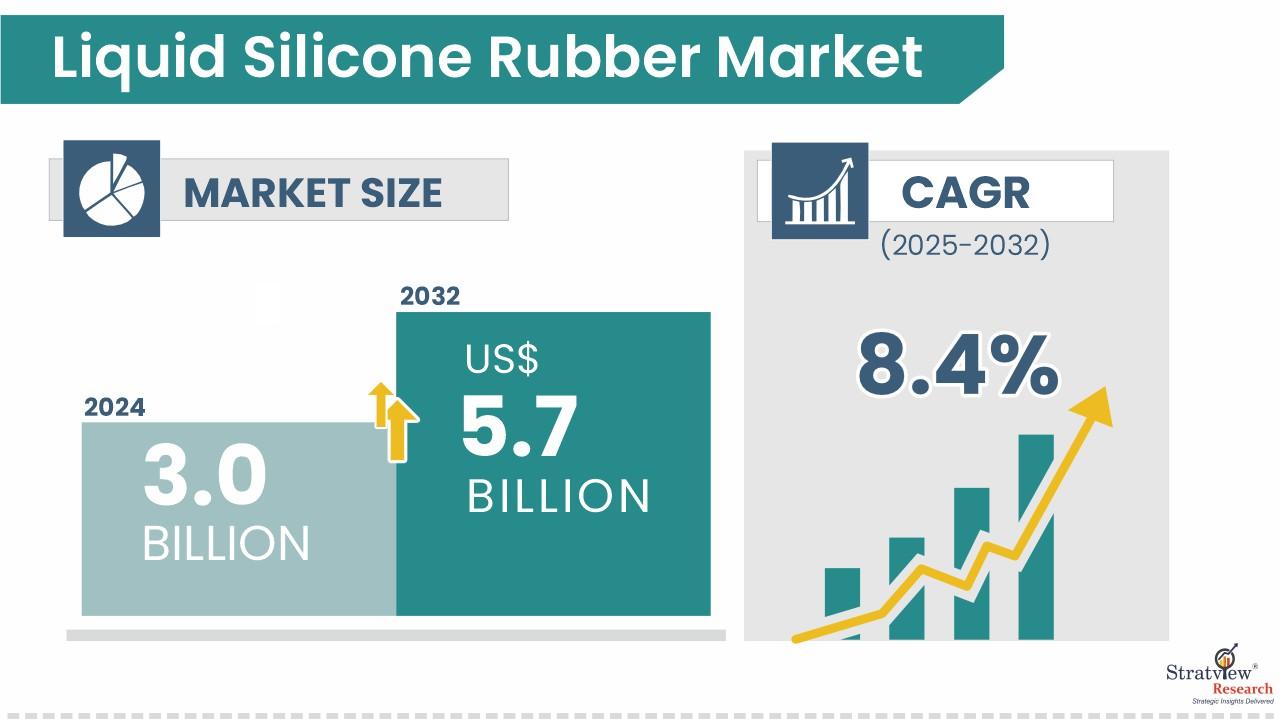

According to Stratview Research, the liquid silicone rubber market was estimated at USD 3.0 billion in 2024 and is likely to grow at a CAGR of 8.4% during 2025-2032 to reach USD 5.7 billion in 2032.

Request Sample Page Now:

https://www.stratviewresearch.com/Request-Sample/792/liquid-silicone-rubber-market.html#form

Market Drivers

One of the strongest drivers is the growth of the healthcare sector. LSR’s biocompatibility, hypoallergenic nature, and resistance to sterilization make it ideal for medical devices such as catheters, valves, baby care products, and implantable components. The rising demand for minimally invasive procedures and wearable medical devices further accelerates adoption.

The automotive industry is another key growth engine. With the push toward electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the need for durable materials that can withstand high temperatures, vibration, and harsh environments has increased. LSR is widely used in gaskets, seals, connectors, and LED headlamps, ensuring safety and performance in demanding automotive applications.

The electronics industry also contributes significantly. LSR’s insulating properties and flexibility make it suitable for connectors, keypads, and sealing components in smartphones, wearable devices, and consumer electronics. The miniaturization of devices and the expansion of 5G infrastructure are creating new opportunities for LSR adoption.

Additionally, technological advancements in processing techniques are enhancing efficiency. Improved injection molding systems and 3D printing with LSR are expanding design possibilities, reducing production costs, and enabling rapid prototyping.

Challenges

Despite its advantages, the market faces challenges. High material and processing costs limit its adoption in price-sensitive markets. While LSR delivers long-term benefits, its initial investment is often higher compared to conventional rubbers.

Complex manufacturing processes also pose hurdles. The specialized equipment and expertise required for LSR injection molding create barriers for smaller manufacturers.

Environmental concerns present another challenge. Although silicone rubber is more sustainable than some petrochemical-based materials, recycling options remain limited. Growing regulatory scrutiny around waste management is pushing manufacturers to innovate in sustainable solutions.

Conclusion

The liquid silicone rubber market is poised for growth, supported by its expanding role in healthcare, automotive, and electronics. While cost and sustainability concerns persist, ongoing technological innovations and increasing demand for high-performance, reliable materials will sustain momentum. As industries prioritize safety, efficiency, and durability, LSR is set to become an indispensable material in shaping next-generation products.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness