Engineering Plastics Market – Strong Growth on the Back of Lightweight & High-Performance Demands

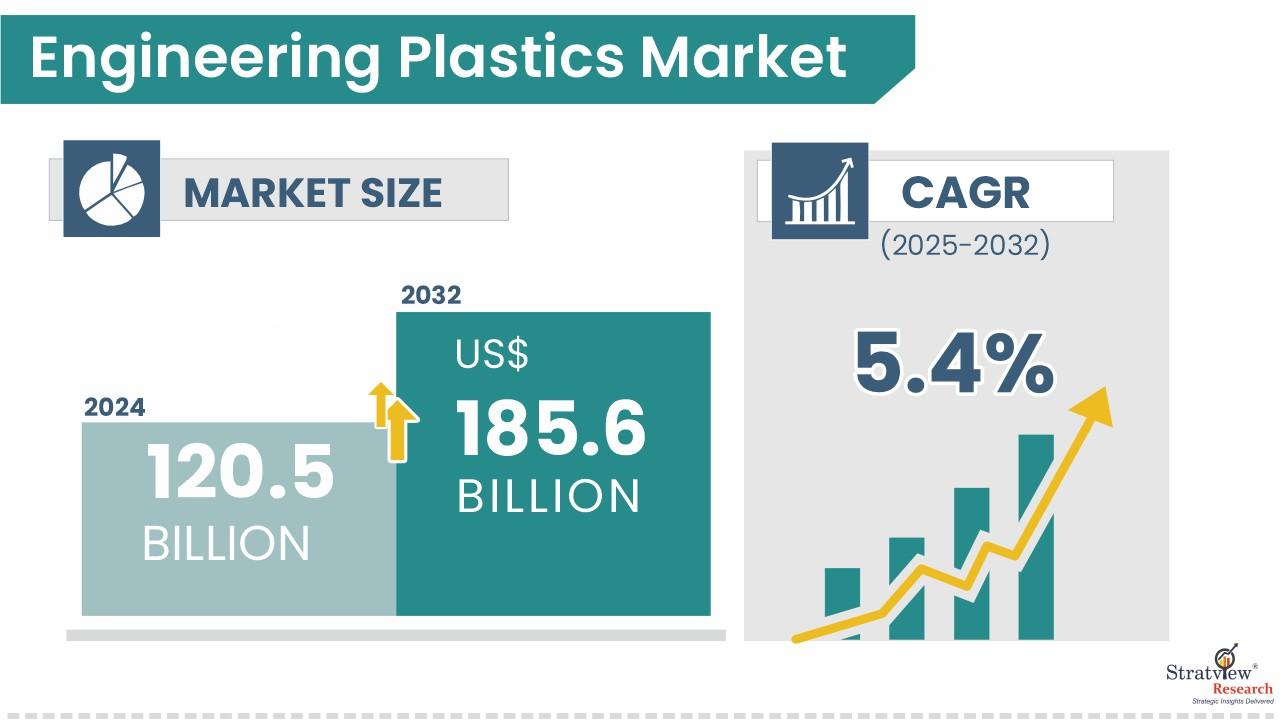

Engineering plastics have become essential in modern manufacturing, used wherever regular plastics fail to meet performance thresholds—for example, when strength, temperature resistance, chemical resistance, or precision are needed. Stratview Research’s suggest that the engineering plastics market was estimated at USD 120.5 billion in 2024 and is likely to grow at a CAGR of 5.4% during 2025-2032 to reach USD 185.6 billion in 2032.

Request a Free Sample Report Here:

https://www.stratviewresearch.com/Request-Sample/963/engineering-plastics-market.html#form

Drivers

- Lightweighting & performance: The pressure to reduce weight in sectors like automotive, aerospace, and EVs is strong; engineering plastics provide alternatives to metals without sacrificing important properties.

- Demand for durability & longevity: In electrical & electronics, appliances, industrial machinery, etc., products face thermal, chemical, and mechanical stresses. Engineering plastics help meet these demands.

- Regulatory & environmental pressures: Both emissions regulations and sustainability goals (recycling, reduced waste) are motivating adoption of plastics that last longer, can be recycled, or reduce weight/fuel consumption.

Trends

- Shift toward bio-based / recyclable engineering plastics: To address environmental concerns, new polymers or modified engineering plastics with recycle-friendly or bio-based feedstocks are increasingly in R&D and limited commercial use.

- Rapid growth in EV & electronics components: As electric vehicles proliferate, components like battery housings, connectors, powertrain covers etc., use more engineering plastics. Similarly, electronics (smart devices, wearables, etc.) demand plastics that can handle heat, precision, miniaturization.

- Asia-Pacific as growth engine: Numerous reports show Asia-Pacific not just leading in volume, but innovation, cost structures, and rising demand across multiple sectors. China and India especially are noteworthy.

- Innovation in processing & additives: Better additives (for flame retardancy, UV resistance, chemical resistance), improved fillers, better molding processes etc., are helping engineering plastics expand into applications that had been too harsh or demanding.

Conclusion

The engineering plastics market is on a strong trajectory. While cost, environmental and regulatory challenges remain, the combination of performance demand, weight reduction pressure, and advances in materials and processing point to continued healthy growth. Businesses that stay ahead in resin innovation, adopt sustainable practices, and align with fast-growing end-users (EVs, electronics, etc.) will be best placed to succeed. The winners will be those who balance functionality, cost, and environmental responsibility—and who scale in regions where demand is accelerating strongly.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness